History of Taskers

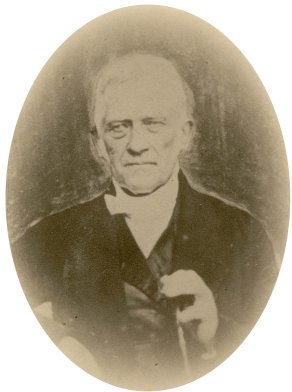

For 170 years, Taskers were a leading manufacturer of a wide range of agricultural implements and machinery, steam and stationary engines and road vehicles. The story began near Andover, in the early years of the 19th century, when Robert Tasker and his brother, William, began what was to become the Waterloo Ironworks.

At the heart of those ironworks was a forge, which must have reminded them of the blacksmith's shop run by their father in Stanton-St-Bernard in Wiltshire. As the eldest son, Robert Tasker would have been brought up to be a blacksmith. But he was ambitious, and left Wiltshire in February 1806.

The cottage in Abbotts Ann where Robert Tasker lived, and in which he hosted prayer meetings. In Abbotts Ann, near Andover, there was a forge owned by a smith called Thomas Maslen. Robert became his assistant. In 1809, he took over the business. The young Robert Tasker was a keen businessman, but more important to him was his strong Christian faith. As a nonconformist he attended Andover Congregational Church. But feeling he needed to do more, he opened his cottage for prayer meetings on Sunday evenings. It seems his nonconformist faith made him some enemies. His neighbours may have found him tiresome.

Landowners in the area, members of the established church, saw any kind of dissent as a threat to their authority. Little work came his way locally. For a while Robert had to rely on his inner courage and resourcefulness, finding customers in places like Newbury and Southampton in order to stay in business.

Second only to his religion were his ambitions for the forge. He knew that an ordinary blacksmith's shop could not supply what the industrial revolution, then nearing its height, could offer to customers of a major ironworks. If he was to succeed he had to take advantage of the situation. To achieve that the forge expanded to become, for a time, the Abbotts Ann Ironworks. Yet it must always have been clear that the village was too inaccessible for what Robert Tasker had in mind, and the site too small to satisfy his ambitions.

The technology of ironfounding was still being developed when Robert Tasker came to Abbotts Ann. But he must have seen that, for example, ploughshares made in a foundry lasted longer than any made by an ordinary blacksmith. The addition of a small foundry to his own forge shows that such lessons struck home. The industrial revolution punished businesses that did not understand or welcome its new technologies and rewarded those that did. Products like the cast-iron ploughshare made some blacksmiths poorer. But another product of the industrial revolution, the Andover Canal, was to offer Tasker a great opportunity.

Riot and Assembly

The Waterloo Ironworks was begun when poor people in farming areas were finding life very hard, and the rich were afraid of a revolution as in France. Population was growing, but people were leaving the countryside to work in towns. Age-old methods of farming were changed. Small fields were consolidated into larger ones, then fenced or hedged. This was 'enclosure'. The war with Napoleon made imports difficult, and so food prices were pushed upwards so that by 1812 grain cost nearly three times as much as in the 1790's. The rural poor were forced from subsistence into desperate poverty.

Farmers got rich, but didn't increase the wages of their labourers. When the war ended in 1815 grain prices fell. However, to safeguaurd their profits, farmers cut labourers' wages and introduced mechanisation. The government also passed laws to limit cereal imports to keep prices as high. Farm labourers had to continue to claim relief under the Poor Law, and even that could be taken away from them. In 1830, around Andover, the bread allowance per man was just half what they were entitled to in 1795.

In this situation rioting was bound to erupt. Its main target was the farm machinery that seemed to be robbing the labourers of work - most hated of all being the new threshing-machines. But innocent parties were attacked too, and the punishment that the law would mete out was to be worse than the rioters expected.

On 20 November 1830 at about 4 o'clock a mob of around 300 men came into the Waterloo Ironworks. They tore down walls and part of the roof, smashed windows, destroyed some half-made ploughs and damaged the foundry crane and waterwheel.

The attack was a pointless and random episode in a wave of agricultural riots which began in Kent known as the 'Swing' riots after 'Captain Swing' - an invented name put to letters demanding better pay and conditions for farmworkers.

John Howell, the Taskers' foreman, was there when the rioters arrived, and tried to stop them. Robert Tasker himself was somewhere nearby. According to one account he was hiding in the timber yard. When the rioters came to be tried, though, he was able to say 'I did not speak to them, nor was I near enough to identify the parties'.

30 men were arrested by Special Constables and 14 were later charged. After a month in Winchester prison, the accused appeared before a government-appointed Special Commission with powers to sentence them to hang or be transported. Four of those charged with 'riot and tumultuous assembly' at Taskers were acquitted. The other ten were sentenced to death. For nine of them this was immediately commuted to transportation for life to Australia. The authorities wanted one, John Gillmore to die, but he too was eventually transported. Two Hampshire men were hanged, however, in connection with other Swing riots, and to add to the misery of all the other convicted men they were made to watch their executions.

Taskers and Steam

Living far from the northern factory towns, Robert Tasker may never have gained any practical knowledge of steam power, even though as a businessman he probably realised his potential.

For nearly 30 years his retirement, the only machines made at the Waterloo Ironworks were ones powered by men, horses or the engines of other manufacturers. Nevertheless, by the 1850's railways were being built everywhere. A line from London to Andover opened in 1854, and in 1859 the Andover-Redbridge Canal, without which the Ironworks would never have existed, was closed. As if to confirm the sovereignty of steam, after a few years a railway line was built along the route of the old canal. Taskers wharf at Upper Clatford was transformed, magically it would seem, into the company's private railway siding.

Although they made none of their own in the 1850s, by the end of the decade Taskers were supplying portable and stationary steam engines made by Clayton, Shuttleworth & Co of Lincoln. This change may well have had to do with the retirement of George Fowle, who had run the company for 20 years in partnership with Robert's brother William. Now it was time for William's sons to take over.

The first steam engines made at the Waterloo Ironworks were three portables in 1865. A portable was an engine meant to drive other machinery. Its own wheels did no more than allow it to be drawn around by horses. Many parts for these first engines were supplied by other manufacturers. To design and assemble them, Tasker & Sons even needed to "headhunt" a man from Clayton, Shuttleworth & Co - the company whose engines they had been selling for several years. Another man came from Blackstones, also in Lincoln. These men from the industrialised east midlands may have been surprised to find the ironworks amongst the green fields and trout streams of Anna Valley.

It may also have seemed strange to them that most of the workforce belonged to families that had lived nearby for generations. It was rare then for the sons of farm workers to be able to work in industry without having to leave the countryside. In a way, although it was not something that they ever planned, it is Taskers' most original achievement

None of the first few hundred engines were "built to drawings". New plans were drawn up for each one and standard parts modified, with the result that every finished engine was unique. However intuitive and craftsmanlike these methods were, they were clearly inefficient. In 1891 a class of closely-related engines was at last established with the 8 horsepower traction Economic.

Progress was marked by Economic in one other way - whereas all previous Tasker & Sons engines had boilers made of wrought-iron, the boiler of this one was entirely made of steel. As a practical alternative to cast or wrought iron, steel only became available in the 1860's. Far more steel than wrought iron could be made in one go. Large components, like boiler plates, were therefore easier and cheaper to make in steel.

In typically Victorian style, William Tasker named his first two sons after himself and his brother. So, in 1858 after Tasker & Fowle became Tasker & Sons, it was again a Robert and a William Tasker who had charge of the business. Robert jnr would never have more than a financial interest in the firm. He turned to farming instead. But William jnr. proved to be the most inventive member of the whole family. Between 1858 and 1873 he lodged at least nine patents; four for improvements to threshing-machines, three for hay elevators and two for ploughs. However, none of William jnr's patents was for a steam engine. There was one more brother left at home. Henry Tasker, seventeen years younger than William jnr. was apprenticed to steam engineers Clayton, Shuttleworth & Co in 1864 and afterwards bought his knowledge of steam back to the family firm.

Tasker and Sons Ltd

In 1896 Henry Tasker handed over ownership of the firm to shareholders. Tasker & Sons became Tasker & Sons Ltd.

Henry was still a director of the company, but it was the end of an era. Things should have got better now - especially as the government was beginning to encourage road transport by easing speed and weight regulations.

In 1902 Taskers stepped in with the first of a standard class of 'light' (just under 3 tons) engine called the Little Giant. Eventually over 300 of these were built, and when enthusiasts today hear the name Tasker, it's the Little Giant they think of.

Unfortunately the success of the Little Giant did not come quickly enough. There was a company liquidation in 1903 and a reformation in 1907, between which two events Henry Tasker retired, ending the Tasker family's involvement with the company that bore their name.

The end of Steam

Then came the First World War, followed by a slump in which the only steam engines called for were road rollers. The very last steam engine built by Taskers was a road roller completed under the shadow of a second company liquidation in 1926. Staff of Tasker & Sons Ltd gathered in front of the company's last steam vehicle, a C Class road roller, in 1927. The man third from the right in the front row is the company receiver.

The new company, Taskers of Andover Ltd, made no effort to revive steam. At some time in the 1930's a last relic of it, a note book with drawings used for making spares, came somehow to be burned in a heating stove, and with that the age of steam at Taskers ended.

Tasker 1932 Ltd

The year after Taskers' last steam engine left the factory in 1927, a new product appeared that would revive the company's fortunes - though not before yet another liquidation a few years later in which the company name was changed to Taskers of Andover (1932) Ltd.

A semi-trailer is a trailer with no front axle. The weight of the front simply rests on the point where the trailer is attached to the lorry. On the Tasker semi-trailer this point of attachment, or coupling, allowed movement in all directions. Because of that it was possible to jack up one side of the lorry or one wheel of the semi-trailer without having to uncouple them first.

This was the product that brought Taskers back from the brink. With all their structural parts being steel, growing production of the various models of semi-trailer led to less and less use for the foundry. Finally, in 1937, iron founding at the Waterloo Ironworks came to an end. Robert Tasker may have turned in his grave, but business continued to improve.

A lorry belonging to a Southampton haulage company, George Baker and Sons Ltd, is here coupled to an early Taskers semi-trailer. The photograph was taken in Tasker's yard.

In 1938, with war looming, the Air Ministry asked for tenders for a trailer able to carry an entire fighter aircraft. Within ten days Taskers submitted not just a design and tender, but a full-size prototype. The contract was won, and in the World War that followed nearly four thousand of these trailers were built. They soon gained the nickname "Queen Mary", being, like the passenger liner, the largest of their kind.

The end

In the later 20th century Taskers shared the fate of many medium-sized companies, becoming first a production arm of a mighty conglomerate, then a casualty of changes taking place higher up. By 1968 the company had adopted the name Tasker Trailers Ltd and had branches in Scotland and near Wigan in Lancashire. But that year the old problem of insufficient capital led to them becoming a subsidiary of Craven Industries Ltd, which was itself owned by the huge John Brown & Co Ltd. The Craven-Tasker group, with a head office at Anna Valley and sites in at least six locations throughout the country, continued making trailers and a variety of agricultural implements until the early 1980's. Then, in 1983, John Brown & Co Ltd sold assets, including Craven-Tasker, to Montracon, a company based in Belfast.

Already having enough manufacturing capacity, Montracon immediately brought 170 years of business at the Waterloo Ironworks to an end. The next year, 1984, the factory buildings were levelled. The site of the Waterloo Ironworks is now occupied by housing.

In World War II, as in World War I, women joined the Taskers workforce. However, it was felt necessary to segregate the sexes at mealtimes