'The fair princess set her maids to work, and she herself cut out each garment. Snow-white silk from Araby and Zazamanc, and silk, green as clover did the princess bring forth, and silks also from Libya and Morocco. The ladies' zeal, it was not small, forsooth; in seven weeks they wrought the robes.'

From the late 12th - early 13th century German epic poem The Niebelungenlied, Chapter 6.

Like the princess in the poem, the nobility of late Saxon and medieval Winchester adorned themselves with silks from Byzantium, Persia and Syria and garments woven with spun gold. By the time of the Norman Conquest, Winchester was renowned for the quality of its embroidered textiles made at religious houses such as the Nunnaminster, where Winchester Guildhall stands today.

Throughout history, spinning and weaving were usually carried out at home, but from Roman times onwards, the well-to-do could afford professionally-made woollen cloth and linens. The imperial fulling mill which supplied the Roman army with cloth throughout the province of Britannia during the 4th century AD was sited at 'Venta', quite likely Venta Belgarum, Roman Winchester.

Winchester was also a major centre for the medieval wool and cloth trade, second in the region only to Salisbury. Everyone span and wove, but the all-important fulling, dyeing, and finishing of the cloth was carried out in the Brooks area of the city, as ready access to water was required.

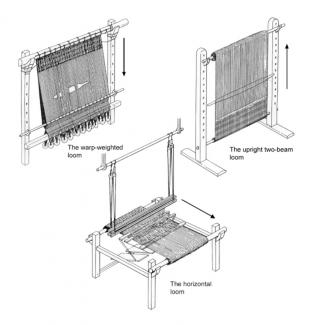

In prehistoric, Roman and early Saxon times the warp-weighted loom was used most for weaving, but by the late Saxon period the upright two-beam loom had begun to replace it. The clay weights needed for the warp-weighted loom are rarely found in 10th and 11th century Winchester- the early medieval ones in the collections are from St Cross, rather than the city.

The burgeoning wool and cloth trade seems to have prompted technological innovation, and the transition to the upright loom. The cloth was woven from bottom to top and the weft (horizontal) threads pushed, or beaten downwards. The bone tools known as pin beaters were particularly suitable for this method of weaving.

Documentary history tells us that the horizontal loom was in use by the later medieval period. Then weavers could work in pairs on the 'great loom' (grant ustil) to make 'burels'- very large pieces of cloth-, in a way that foreshadowed the factory system of the Industrial Revolution.

The conditions that preserve textiles over long periods of time are rarely found in north-western Europe, and most archaeological discoveries are very small, fragmented and fragile. There are occasional survivals, such as the gold thread found attached to the skull of a burial on Cathedral Green, and at the bottom end of the comfort-scale, a fragment of a hair shirt from another burial on the same site. The tools and equipment used for making and working cloth survive very well, however, and have been unearthed everywhere in Winchester.